|

benchtop

bond tester in a handheld package MIZ®-21R Sondicator |

|

| The S-21R offers more power and capabilities than

benchtop bond testers. It incorporates all of the bond testing technology, packaging, and

user interface enhancements of the MIZ-21SR.With much greater sensitivity, it’s more

effective in detecting defects, yet it costs less than benchtop testers. The user

interface makes the S-21R much easier and faster to use than other bond testers.With the

same high-contrast display as the MIZ-21B and MIZ-21SR, it provides excellent visibility.

And at less than four pounds, the S-21R is much smaller than benchtop bond testers, so

inspectors can easily maneuver in limited access areas. It stores up to 40 test

configurations (20 Sondicator mode, 20 Resonance mode) and can operate more than 12 hours

on one battery charge. |

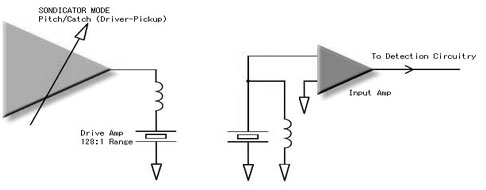

Sondicator technology: A

Sondicator probe uses a dual element piezoelectric transducer to introduce sound waves

into composite materials. One of the transducer elements is a transmitter, the other a

receiver. If the material being inspected is undamaged, the sound waves travel through the

material in a predictable time period. Any disbonds or delaminations within the inspection

zone attenuate the sound waves (and the material vibrations that they create). This

decreases the energy transmitted beyond that point.

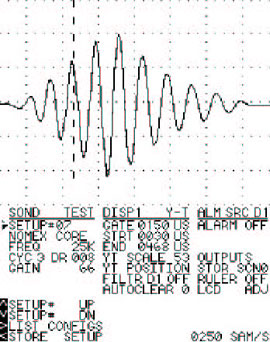

The sondicator method provides digital signatures defining normal and abnormal conditions,

displayed as a classic RF waveform format or as an XY screen plot. An experienced

technician can interpret these signatures and determine the location and relative size of

the disbond condition. |

|

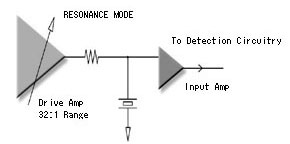

You can use the S-21R in the Sondicator mode to test for

disbonds or delaminations in composite and metal-to-metal bonded materials. Or, in the

Resonance mode, it can perform more specific thickness checks, confirming a good sound

path through a section of composite, or identifying which layer is disbonded.

The S-21R’s broad frequency range supports a wide range of applications and probes. |

| Resonance

technology:Closely related to traditional ultrasonic inspection but in a lower

frequency range, this variable frequency test electronically monitors the impedance

changes of the contact transducer’s piezoelectric element. Small variations in the

tested structure alter the mechanical loading (particle vibration) on the transducer face.

This in turn affects the transducer’s electrical impedance. In adhesive bonded

materials,changes in the thickness (caused by disbonds) affect the phase and amplitude of

the signal at the transducer’s resonant frequency. In multi-layered structures, phase

relates to the relative depth of the disbond. |

|

| Here's the smallest, lightest, most convenient

way to perform bond testing. The S-21R can do everything a benchtop tester can do, yet it

costs less and is much easier to use. Detect impact damage, disbonds, delaminations, and

other anomalies in honeycomb and composite materials. Improved sensitivity to flaws makes

testing more accurate. Zetec's display technology offers excellent contrast and

resolution. |

|

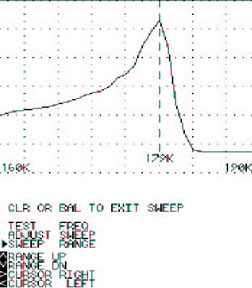

The Resonance Sweep display automatically calculates the

resonant frequency of the transducer. This instrument identifies the frequency to within 1

kHz for optimum test sensitivity

|

Display

Modes

- XY Impedance Plane

- Bar Graph

- YT Sweep

- Combined XY/YT Sweep

Memory Non-volatile (data retained with power off):

- Stores 40 test setups: 20 sondicator and 20 resonance

- Stores 10 screen images for review or comparison

- Stores up to 10 reference points with numeric label in resonance mode

Frequency Selection

- Sondicator mode: 0.5 kHz to 500 kHz (external tuning) or 4 pre-selected frequencies of

7, 14, 25, and 40 kHz (internal tuning)

- Resonance mode: 0.5 kHz to 500 kHz

Filters

- Adjustable high-pass, low-pass, and bandpass filters

- On-screen numeric read-out of cutoff frequency.

Alarms

- Audio alarm with adjustable volume

- Visual LED alarm

- Alarm area is shown on the display; alarm box size and positioning are independently

adjustable

- Alarm triggers either inside or outside of the gated area

- TTL, visual, and adjustable audio output alarms are provided

- Headphone outputs

- Optional probe with LED alarm that lights when user-specified parameters are exceeded

Probe Configuration Internally switches to interface with probe

configurations

Operating Variables

- Burst length in the transmitted pulse is adjustable from 1 to 9 cycles

- Combined transmit drive/preamp gain adjustable over 1 to 128 range

- Analog amplifier gain adjustable over 48 dB (1 to 255 range)

- Optimize the flaw response with adjustable DELAY gate for XY signal set-up

|

The display provides a 60-degree viewing angle.

|

Use the YT display for the initial test setup in

Sondicator mode. The sampling gate detects changes in phase and amplitude of the YT signal

and converts this to the XY vector display. |

|